- Joined

- Dec 3, 2009

- Messages

- 22,403

- Reaction score

- 238

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

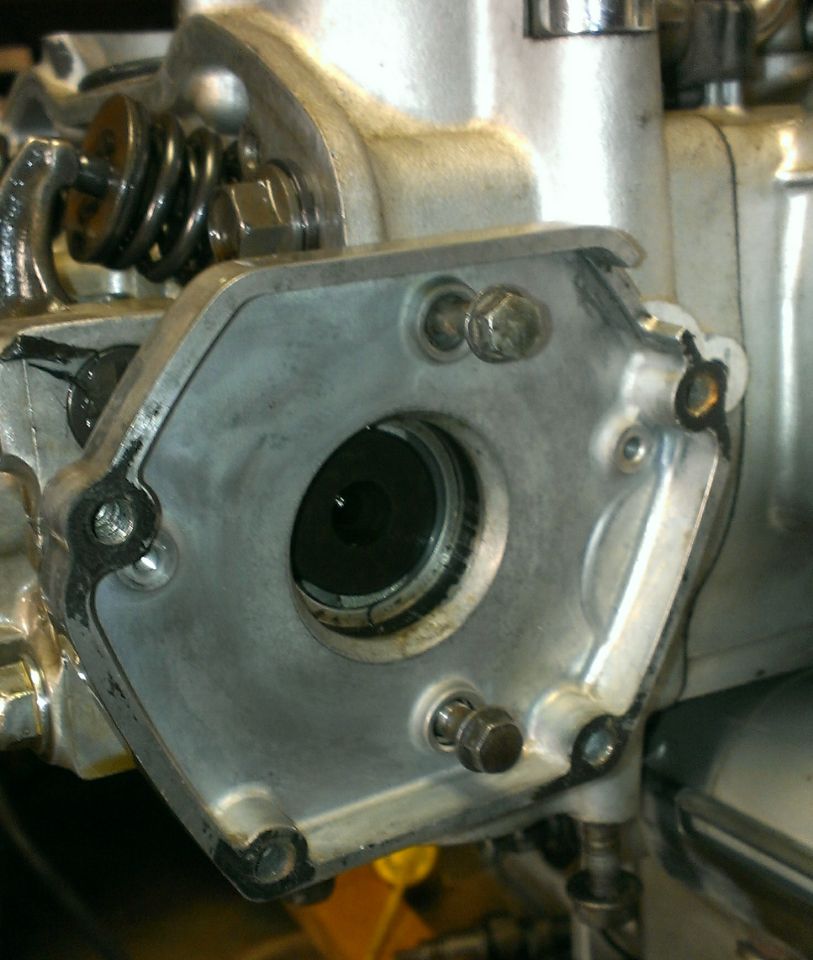

This 1200 F.I model right cam housing could work on the left or right head but the housing not being deep enough for the electronic module presented other problems....

So I went forward with plans to modify the sexy C5 GL1000 housing.....

With the C5 module re-fitted to the GL1000 housing..time to make a drive off the left head..

Cam center drilled and tapped to M8..

Back on the bike..

[video]https://www.youtube.com/watch?v=EUMrJAAFlrE&feature=youtu.be[/video]

Next is fit the C5 housing to the head.

To be continued..

So I went forward with plans to modify the sexy C5 GL1000 housing.....

With the C5 module re-fitted to the GL1000 housing..time to make a drive off the left head..

Cam center drilled and tapped to M8..

Back on the bike..

[video]https://www.youtube.com/watch?v=EUMrJAAFlrE&feature=youtu.be[/video]

Next is fit the C5 housing to the head.

To be continued..