- Joined

- Dec 3, 2009

- Messages

- 22,409

- Reaction score

- 246

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Sub chapter of 1200 install....

I was going to install the C5 on the rear of the 84 1200 engine but not being accessible for reprogramming won't work for me.

Here's my plan to make the C5 easily accessible.

Using an 1100 ignition housing which I'll mount to the belt cover.....

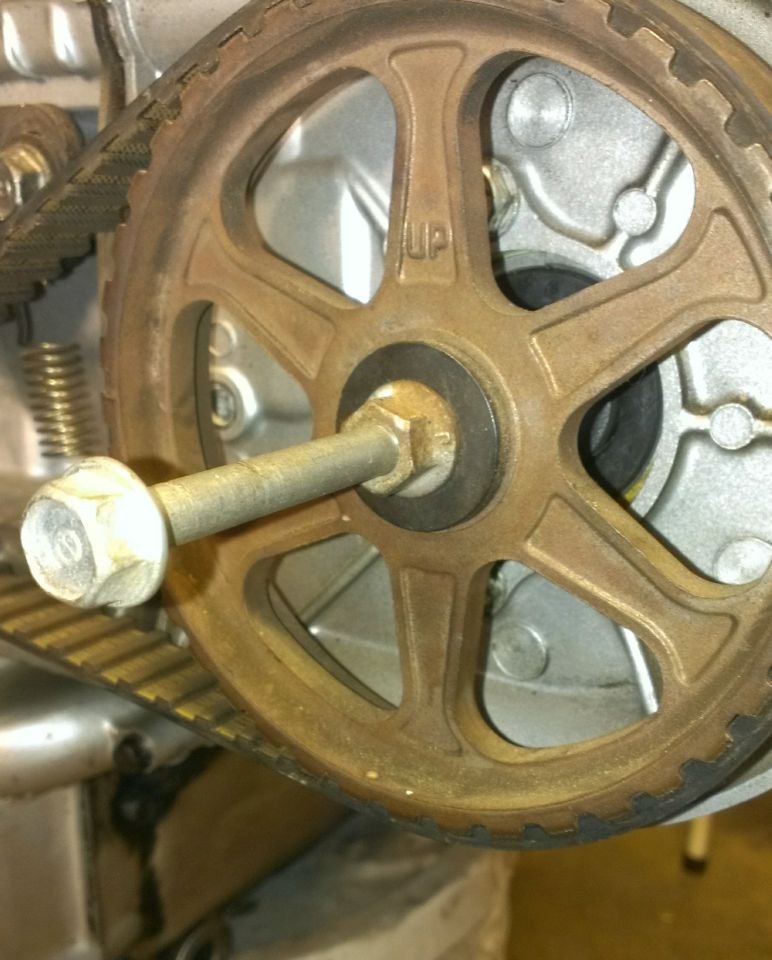

Original cam bolt removed and replaced with a longer bolt, jamb nut to secure gear......... Cut off hex head and thread it.......

End result....A spinning rod to attach C5 pickup wheel to.

I was going to install the C5 on the rear of the 84 1200 engine but not being accessible for reprogramming won't work for me.

Here's my plan to make the C5 easily accessible.

Using an 1100 ignition housing which I'll mount to the belt cover.....

Original cam bolt removed and replaced with a longer bolt, jamb nut to secure gear......... Cut off hex head and thread it.......

End result....A spinning rod to attach C5 pickup wheel to.