Lawrence954

Active member

Is there an alternate method to setting the float level on the GL 1000 carbs without the float level gauge (HC 23892)? The photo in the manual is difficult for me to interpret.

Dissconnect/reconnect cables with the carbs to the side before bolting them down is the easiest.Lawrence954":2dy6a20h said:After reading Randakk's GL1000 floats 101 I see exactly what I did wrong. Oh well, I'll just suffer struggling with the throttle cable remove/replace. The worst part of the whole process of pulling the carbs in my opinion.

***[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=208378#p208378:27asboua said:Lawrence954 » Sun Feb 03, 2019 4:21 am[/url]":27asboua]

I've pulled the carbs and correctly set the float level to 21mm. To bench test it I attached my dirt bike tank with 3 gallons of gas. The two the right side leaked badly and the two on the left showed signs of slightly leaking although it may be attributed to the air box getting flooded from the two on the right. Is the method I used an accurate way to test them? If it is, then the new needles and seats that I installed are junk. I examined them with a magnifying glass and they appear ok. Someone in this thread used a vacuum method but I don't know how to perform that test. If a full tank of fuel is not enough pressure to cause float problems on my KTM then I would think it would be a good way to test the Honda floats.

Great information. :salute:[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=208384#p208384:ryulabmw said:pidjones » Sun Feb 03, 2019 11:49 pm[/url]":ryulabmw]

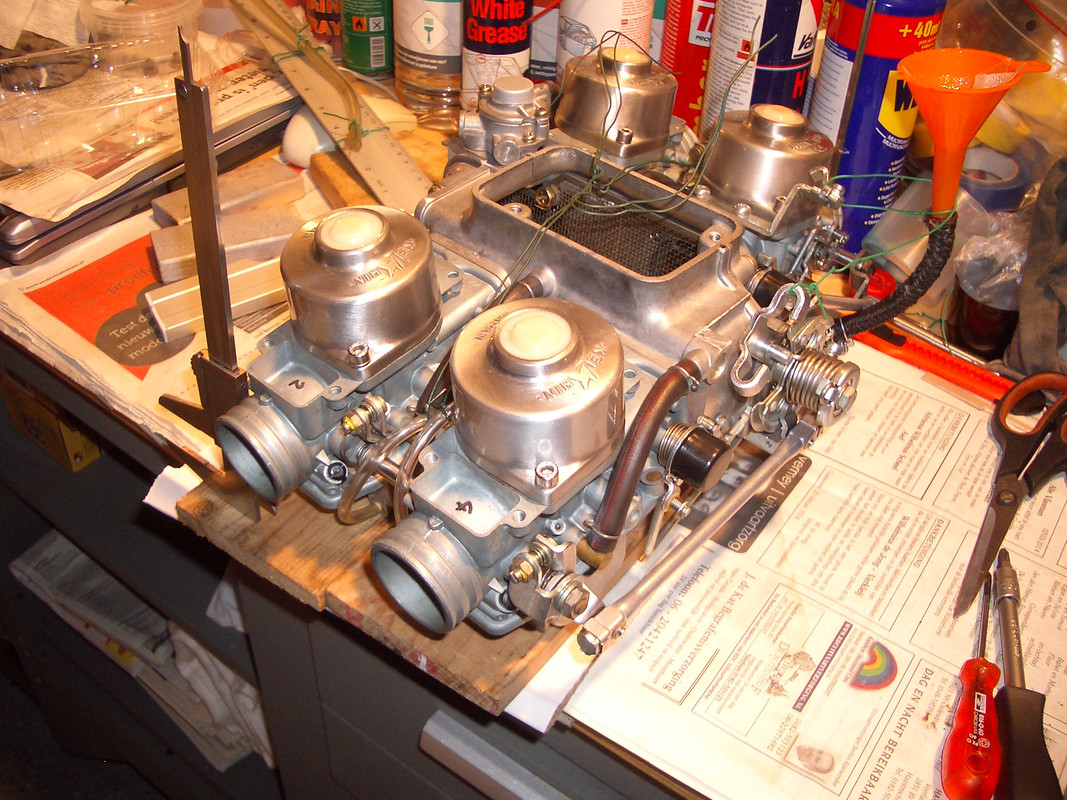

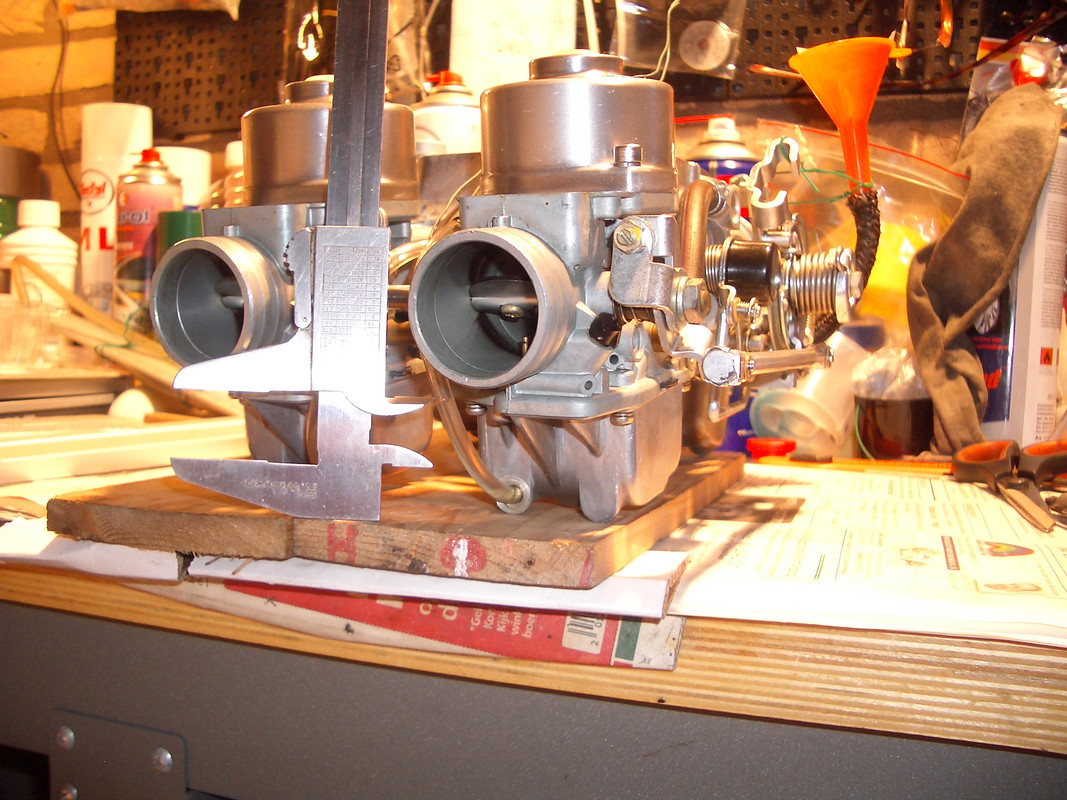

Are you certain the floats are where the leak is? There is also the large o-ring between the two plenum haves, and an odd gasket with a tall cross-section between each carb and the plenum. BTW, using 91% isopropyl alcohol is a bit safer and easier to clean up than gasoline. Vacuum is not so much good for testing the floats as it is good for testing the other seals. A MightyVac can be reversed and provide the same pressure as the GL1000 fuel pump, however. This shows the rack upside-down for vacuum testing. An initial test fof big leaks before the alcohol. Then they are flipped, alcohol put in, the pump connection switched (as shown), and pressure monitored on an automotive fuel/vacuum gauge (connected to the tube out the top in the photo). Pump and gauge available at Harbor Freight.

Enter your email address to join: